Loomis Industries has set the standard for automation, productivity and flexibility.

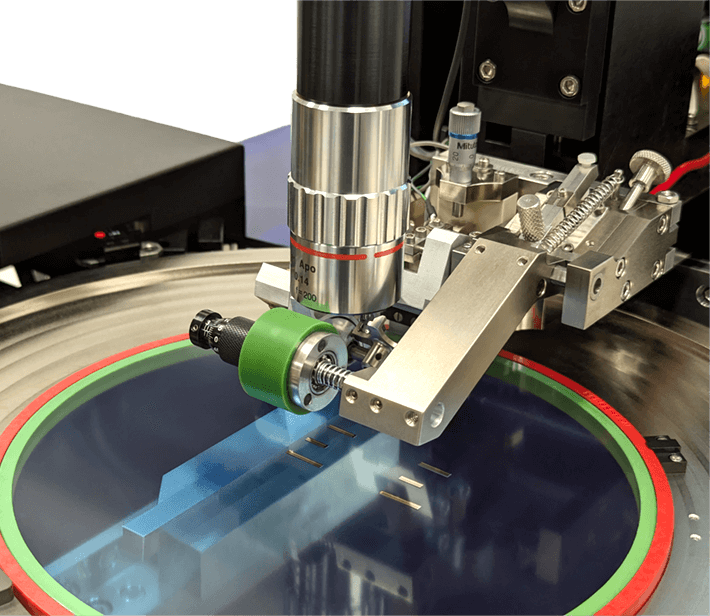

These machines are ideal for cleaving and dicing laser diodes, optical detectors, MMICs, transistors, light emitting diodes, and more.

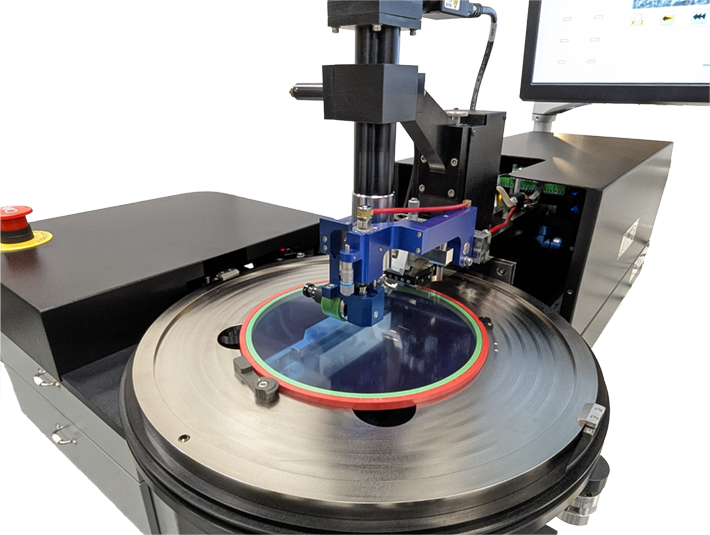

Cutting Edge automated III-V Laser Diode and Wafer Processing

Speed, product quality and yield speak for themselves. Call us at 707-963-4111 or send us a message for information or a demonstration.

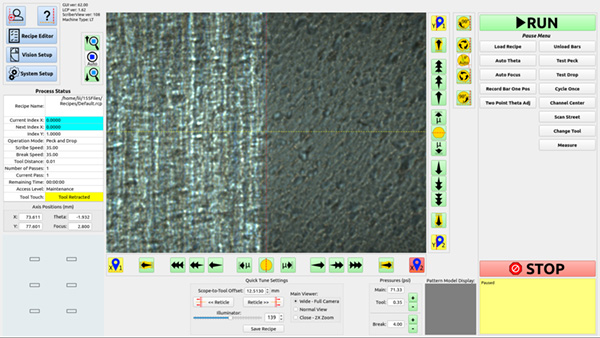

Software Control Package

Ease of Operation

The Loomis Software Control Package has the features for processing your material efficiently.

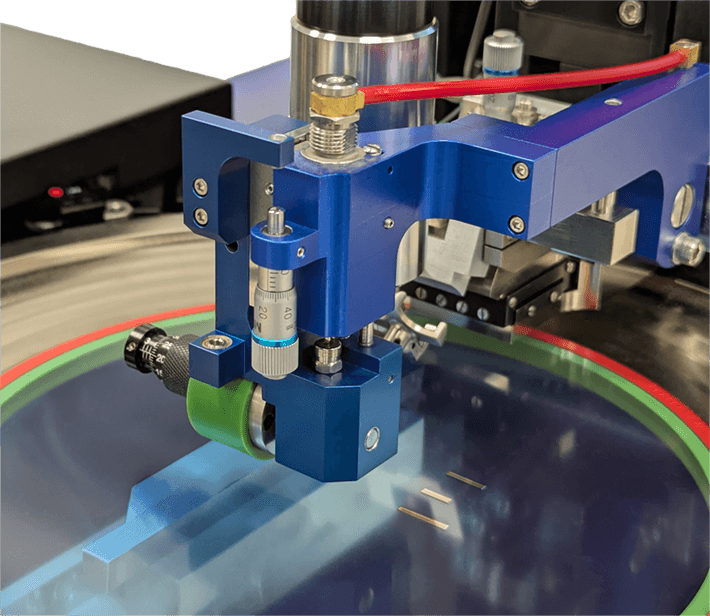

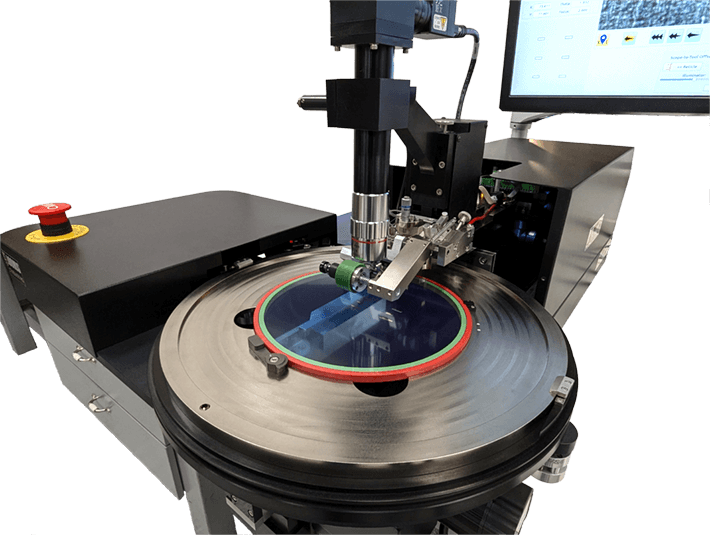

Loomis dicing machines are driven by a computer system incorporating advanced positioning technologies, a real-time imaging system, and pattern recognition. The control software, developed with extensive customer input, accommodates specific user requirements, fully controlling speeds, pressures and other specifics about your wafer. The LSD-155’s highly refined vision algorithms find, align, and process your material with minimal operator supervision.

Once a recipe has been developed, an operator only needs to load the material and press “Start”, allowing the machine operator to perform other tasks.

What Loomis Customers Have to Say

Ready to Increase Production?

We take an active role in helping you define processes that maximize yield.