Products: LSD-155Lt

Cutting Edge automated III-V Laser Diode and Wafer Processing

Speed, product quality and yield speak for themselves. Call us at 707-963-4111 or send us a message for information or a demonstration.

LSD-155Lt

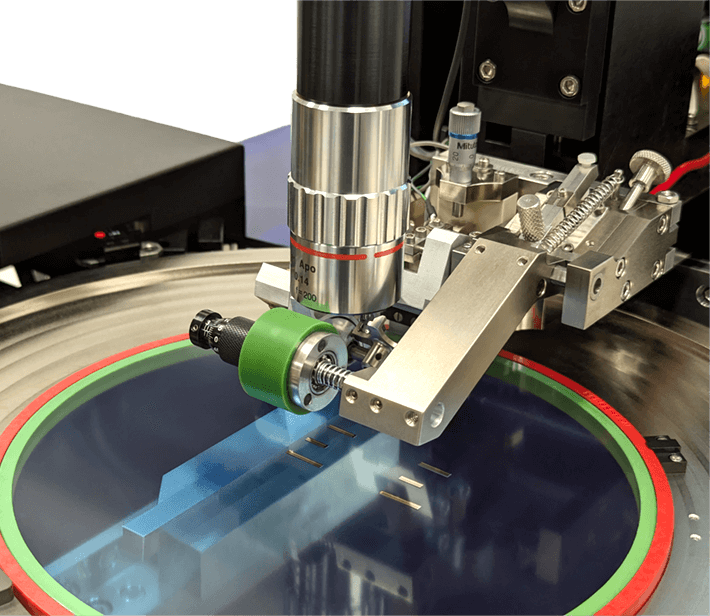

Fast, focused precision using pivoting break wheel technology.

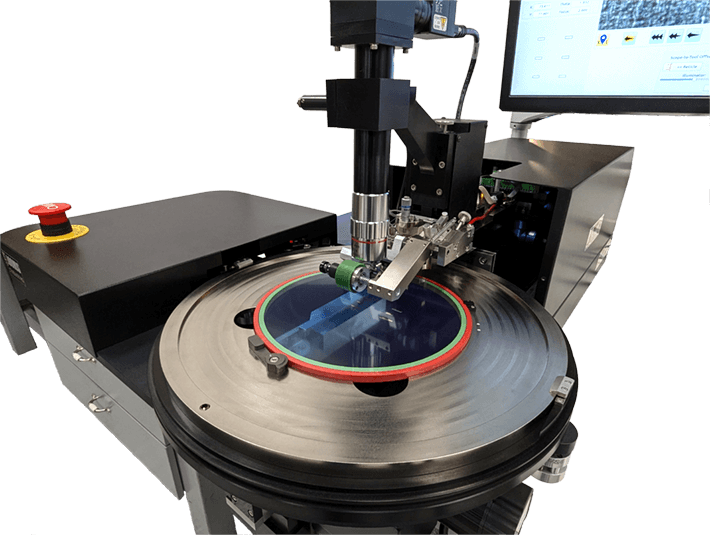

The LSD-155Lt can be configured to function with your existing equipment and process requirement by using the same common wafer holding media and accessories as the LSD-155, except for the break bar. A variety of scribe tools, objective lenses, mandrels and break wheel options are available to optimize the process to your specific application.

Key Advantages

Operator Productivity: Fewer transfer, alignment and process monitoring operations are necessary. Your operators can perform other essential tasks.

Reduced Transfer Operations: Minimal material handling means fewer alignnment processes and higher levels of throughput.

Reduced Redundancy Requirements: 2 Loomis LSD-155Lt machines provide full process redundancy. Equipment limited to scribe only or break only require the purchase of 4 machines for full redundancy.

Automation

- Automatically processes small grids, or arrays of laser bars for dicing, cleaving high quality mirror facets, and dicing wafers.

- Uses advanced automation features that allow the high resolution

vision system to process your wafers with micron-level accuracy. - A tuned, low-inertia scribing module allows fast peck speeds, while

maintaining optimal peck quality. - Multiple cleaving options allow the LSD-155Lt to be configured

to optimize cleave quality and speed.

Features

- Loomis diamond tool-holder with precise force, positioning, low inertia and high speed operation

- Limited-contact cleaving options

- Ring pair, saw frame and Loomis square frame compatibility

- Smooth, accurate, air-bearing control in X and Y axis

- Fully automated alignment and processing

- High-resolution digital camera with autofocus and interchangeable Mitutoyo Objective Lenses

- Advanced machine vision algorithms for pattern recognition, channel and theta alignment

- Modular construction and design that minimizes and simplifies maintenance

- Password protected access for operator, technician, and maintenance level personnel

- Full 360 Degree hands-off material rotation for processing material on multiple axis

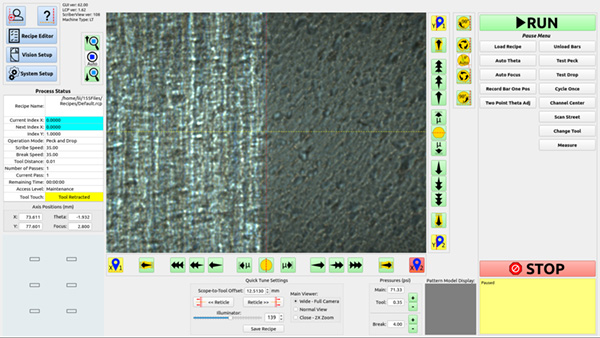

Software Control Package

Ease of Operation

The Loomis Software Control Package has the features for processing your material efficiently.

Loomis dicing machines are driven by a computer system incorporating advanced positioning technologies, a real-time imaging system, and pattern recognition. The control software, developed with extensive customer input, accommodates specific user requirements, fully controlling speeds, pressures and other specifics about your wafer. The LSD-155’s highly refined vision algorithms find, align, and process your material with minimal operator supervision.

Fully Automatic Mode

Our system has the flexibility to run in full-automatic or manual modes and can switch from one to the other.

Once a recipe has been developed, an operator only needs to load the material and press “Start,” allowing the machine operator to perform other tasks.

Every facet and feature of a Loomis scribe tool exists to create the optimum scribe line. The leading edge of the diamond point encourages ductile flow of material around the point as it travels across the wafer, much like the flow of water around the keel of a boat.

The trailing edge is polished to incredible sharpness and is responsible for the stress crack that travels down into the wafer. Lines created with our diamond scribe tools break cleanly and leave edges on the resultant dice that have integrity and strength.

The dice are clean and ready for "die attachment" or coating without further processing.

The Loomis scribe system outperforms all other scribing systems for repeatable optimal scribe lines.

Ready to Increase Production?

We take an active role in helping you define processes that maximize yield.